My Sharpening Process

Geeking out on knives and blades of all kinds has always been an interest, yet it wasn’t until 2020 when getting better performance out of my tools really struck me. After a lot dedicated practice on whetstones, I finally hit some basic milestones for any sharpener. Things like, push-cutting1 paper and cutting arm hairs are fairly innocuous, for whatever reason it’s been an update to how the mind works when I use any edged tool. Constantly questioning the strategies implemented and honestly assess what’s working and ditching what isn’t.

My system incorporates all sharpening fundamentals to be found in classic systems like the fixed angle set of stones from Lansky. I must have been about 10 years old when Ma bought those for me on the spot at Gander Mountain or some such place. The sales gent was convincing, he said the tools could bring back any knife, and shared some advice about being skeptical who you loan your stuff. His buddy had cut electrical wires, truly messing up his knife edge. I cracked the case of stones open periodically and put seriously ineffective practice scratches all over dozens of blades. Then there were the whetstones I bought impulsively online because that is simply sensible first-year college student dormitory kit.

Once again, these bricks became fidgets and fairly mindless practice for too long on the shelf —intermittently unsharpening and scratching bevels haphazardly. Eventually, the global pandemic prompted me to read more, and I’m quite thankful that technical training for sharp results made the list.

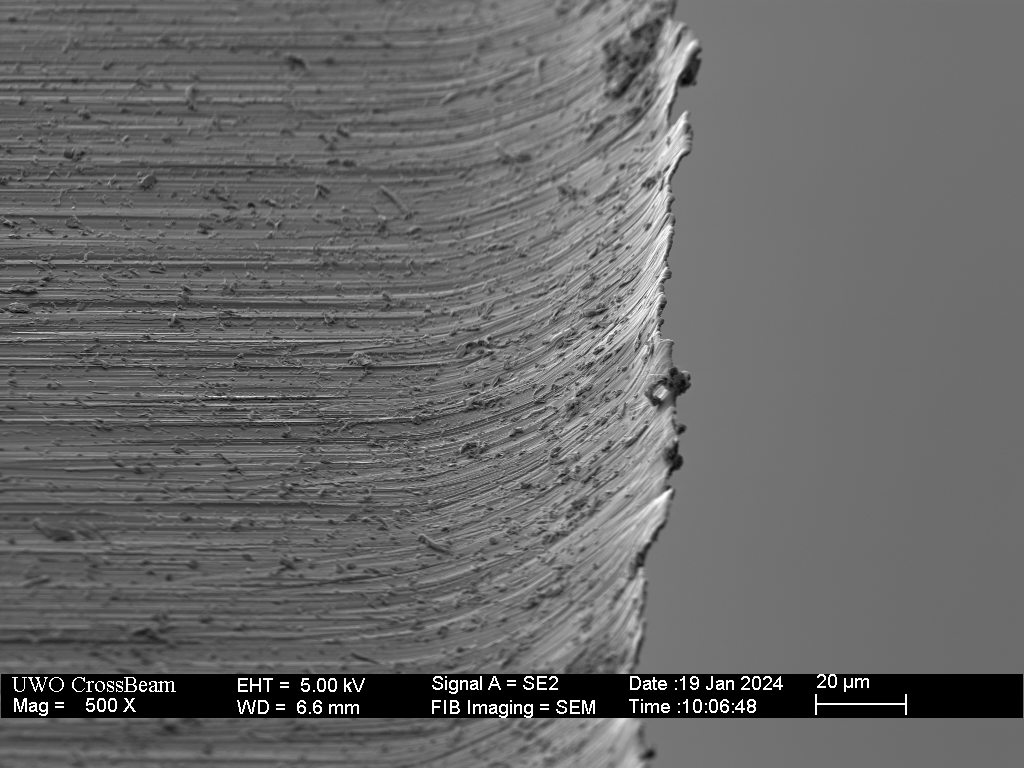

I was finally forming and feeling burrs2, refining edges enough to find performance differences between edges. This sort of discovery sells itself, in my eyes, so I was soon down rabbit holes like edge geometry, grits, and a mess of other topics we could discuss here. Suffice to say, I knew enough to be sharp-dangerous (dull knives are dull-dangerous, folks).  Science of Sharp Electron Microscopy Image of a Burr

Science of Sharp Electron Microscopy Image of a Burr

Quality abrasives and attentive technique, regardless of the sharpening system, will produce quality results. Likewise, improper technique with quality abrasives will produce poor performance. For the last six months, I’ve continually tested, modified, and improved skills with a 1”x 30” belt-driven sharpening system with a fixed angle guide. Larger format sandpaper spinners are common knowledge in the knife industry, enthusiast community, and many general knife-users may notice a grind pattern from a factory blade and presume it had to be machined into “like a wedge slicey shape” somehow. A common misconception assumes that edges finished at the factory, or any edge finished on motor-driven belts could be cooked, referring to heat ruining the temper of the blade. Likewise, skeptics may claim belts cannot reach the refinement necessary for “true sharpness”. It’s good to be aware that over-heating a hardened steel will weaken the underlying structure and performance. Thankfully, for sharpening, heat is straightforward to avoid with lower speed belts than used during a knife’s construction, a light touch to finalize the apex, and stropping strokes to further refine things.

The same fundamentals are applied whether it’s freehand whetstone, a fixed angle system with stones, or tiny stones embedded into a belt and spun with a motor.

Sharpening should always entail removing the least amount of metal for the most amount of cutting ability. There’s surely a time and place for whetstones, and I enjoy practicing with them regularly. I just bring up the comparison of systems because it’s easy overestimate the importance of one system over another and not the skills or attentiveness behind the worker doing the job. Plenty of beautiful Japanese finishes have been damaged by unsteady hands with whetstones. Just the same for new learners with power tools.

|  |  |

|---|---|---|

| Common grinder for knife-making | Popular hobbyist and professional sharpening system | My preferred sharpening machine format |

The tool and customer ultimately guide the finish each item deserves. If a blade isn’t as slicey as it could be and there’s no signs for wear, then let’s take the angle down a bit and get more performance via acute geometry. If a knife is consistently chipping and the user can’t help putting the edge through dirty root vegetables, chopping kindling, etc., then we can go with more stout cutting geometry and convex to the apex. These strategies will get the more work done with the tool and prolong its life as each sharpening becomes easier requiring less damage removal.

People have been making dull things sharper for centuries, but credit is certainly owed to some modern mentors. Cliff Curry and his Custom Cutlery Shop in Maui, Hawaii helps sharpeners bring efficiency and performance to their customers. While I hope to make content showcasing my skills and growth over time, check out his discography to better understand the belt-based systems and sharpening fundamentals if you’re curious.

In the meantime, I’ve cobbled together a YouTube Playlist and select readings for a snapshot of how my brain works and why punching into work with a bench grinder is such a good fit.

Push cutting - cutting motion traversing the blade perpendicular through an object focusing on one area of the edge its apex (i.e. not drawing or slicing through the object, which gains mechanical advantage) ↩︎

Burr - deformed metal at the apex of an edge. For an excellent review of burrs, misconceptions, and guidance on the importance of refining them, check out this excellent Science of Sharp article ↩︎